Seeing Heat from Above: How Drone Thermal Inspections Protect Commercial Roof Investments

Commercial roofs rarely fail overnight. Leaks, trapped moisture, and insulation breakdown usually start as small, invisible problems that quietly erode your asset value. By the time you see water stains inside the building, the damage is already expensive—and often disruptive—to fix.

Drone-based thermal inspections change that equation.

By combining high-resolution infrared (thermal) imaging with aerial photography, we can quickly identify trouble spots across large commercial roofs—without scaffolding, risky walk-arounds, or shutting down operations. For asset managers, facility teams, and marketing or communications leaders, this is not just a maintenance tool; it’s a strategic way to protect brand, budgets, and the occupant experience.

What Is a Commercial Roof Thermal Inspection by Drone?

A drone thermal inspection uses an aerial platform equipped with:

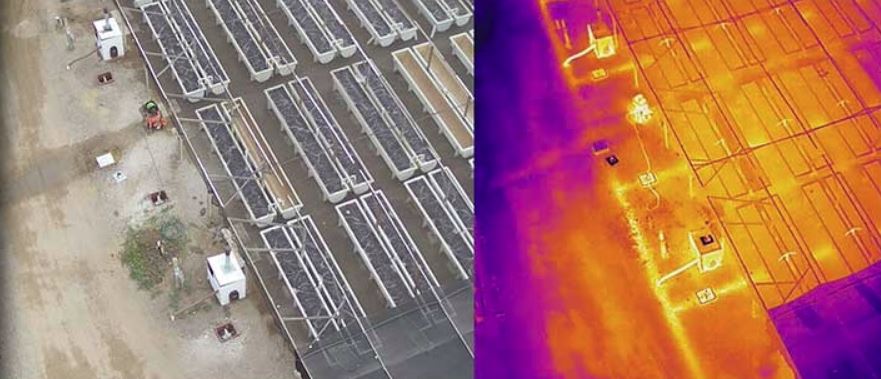

- A high-resolution RGB camera for visual documentation

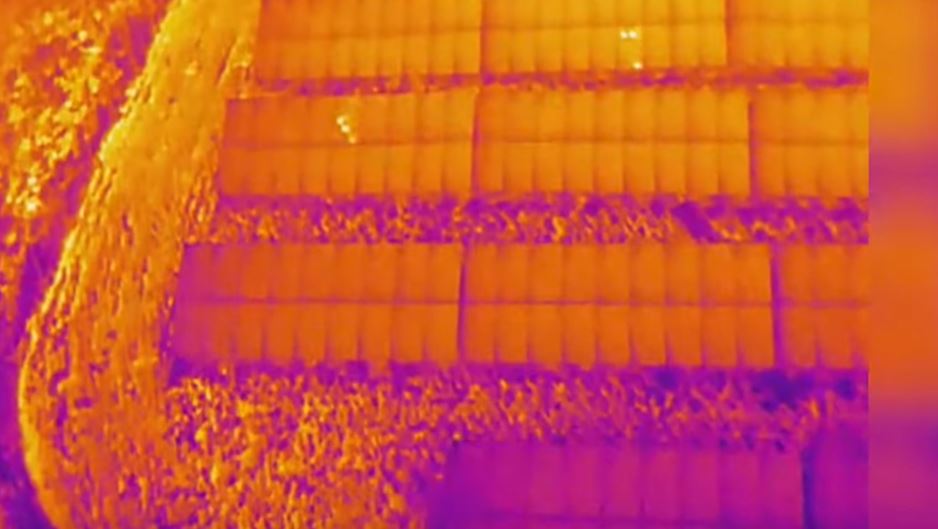

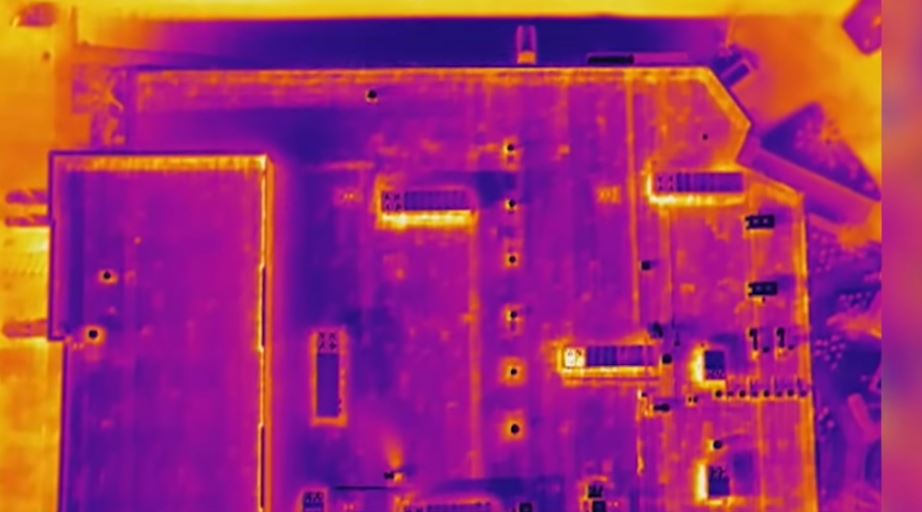

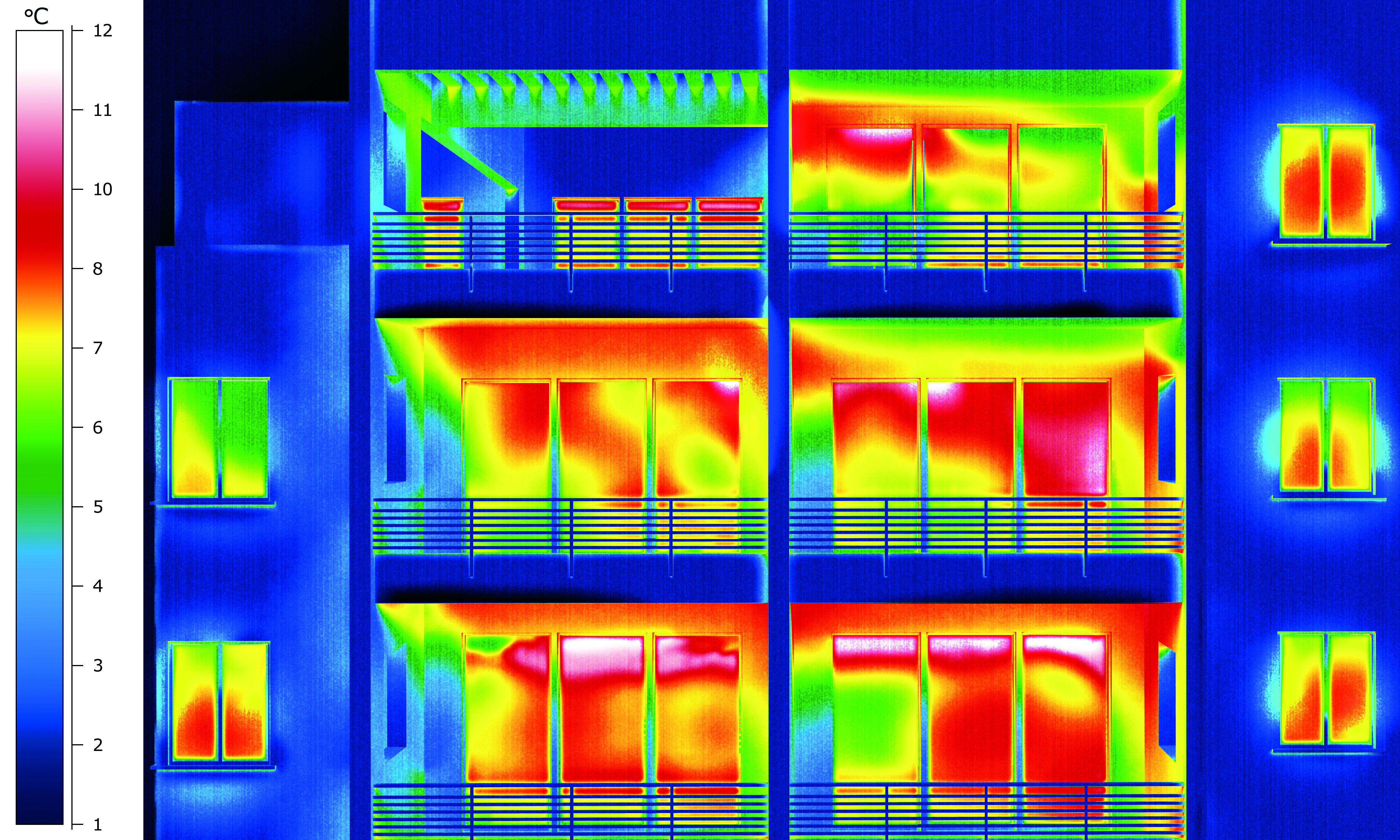

- A thermal (infrared) camera that measures subtle temperature variations across the roof surface

Every object emits infrared radiation based on its temperature. The thermal camera detects this and translates it into an image, where warmer and cooler areas are represented by different tones. On a commercial roof, those temperature differences can reveal:

- Areas of trapped moisture beneath membranes or coatings

- Compromised insulation that’s leaking energy

- Ponding water or drainage issues

- Thermal bridging around penetrations, edges, and rooftop equipment

- Heat signatures that may indicate mechanical or electrical issues with rooftop units

The drone flies a pre-planned grid pattern over the roof, capturing overlapping thermal and visual images. These are then stitched, analyzed, and mapped into a comprehensive report your team can act on.

Why Thermal Drone Inspections Matter to Decision Makers

For decision makers responsible for capital budgets, risk management, and brand reputation, drone thermal inspections deliver value in several critical ways.

1. Early Leak Detection and Moisture Mapping

Traditional inspections often rely on what inspectors can see at eye level—cracks, blisters, visible damage. By the time water shows up inside, moisture has usually migrated through layers of roofing, insulation, and structure.

Thermal imaging can detect temperature anomalies consistent with moist insulation long before interior leaks appear. That means:

- Targeted repairs instead of full system replacement

- Reduced interior damage to ceilings, finishes, and equipment

- Shorter disruption to tenants and operations

This is especially valuable for large roofs—warehouses, hospitals, schools, office parks—where walking every square foot thoroughly is impractical.

2. Energy Efficiency and ESG Reporting

Insulation failures and air leaks don’t just impact comfort; they show up on the energy bill. Drone thermal inspections can reveal where conditioned air is escaping or where insulation has lost performance.

For organizations focused on ESG goals, LEED certifications, or sustainability reporting, thermal maps and documented improvements provide:

- Evidence of energy-loss hot spots before remediation

- Visual proof of corrective actions after repairs or upgrades

- Compelling visuals for annual reports, stakeholder updates, and presentations

It’s a technical service that can be translated into clear communication for executives, investors, and the public.

3. Better Capital Planning and Warranty Documentation

Roof systems are major capital assets. Drone thermal inspections help you manage them like the long-term investments they are.

- Benchmarking condition today, then comparing over time

- Supporting warranty claims with time-stamped imagery and thermal data

- Prioritizing which sections need attention first instead of guessing

- Aligning roof replacement decisions with budget cycles and building strategy

When you can see the entire roof at once—visually and thermally—it’s much easier to justify your capital requests with data, not anecdotes.

4. Safety, Liability, and Downtime Reduction

Sending staff or contractors onto a roof always carries risk—especially when surfaces are wet, icy, or cluttered with equipment.

Drone inspections dramatically reduce the need for rooftop foot traffic, helping:

- Lower the risk of slips, falls, and OSHA incidents

- Minimize disruption to normal operations

- Provide a faster first assessment after storms, hail, or wind events

In many cases, the drone can be deployed quickly after severe weather to document conditions for insurance and internal risk teams before anyone physically steps onto the roof.

How a Professional Drone Thermal Inspection Process Works

While every building is unique, a well-run thermal inspection follows a disciplined process.

1. Discovery and Scope

We start with a conversation:

- Building type and use (office, industrial, healthcare, education, etc.)

- Roof construction (membrane, built-up, metal, coated systems)

- Known trouble areas, history of leaks, warranty status

- Access limitations, nearby airspace considerations, and operational constraints

This ensures the flight plan, camera settings, and deliverables match your goals.

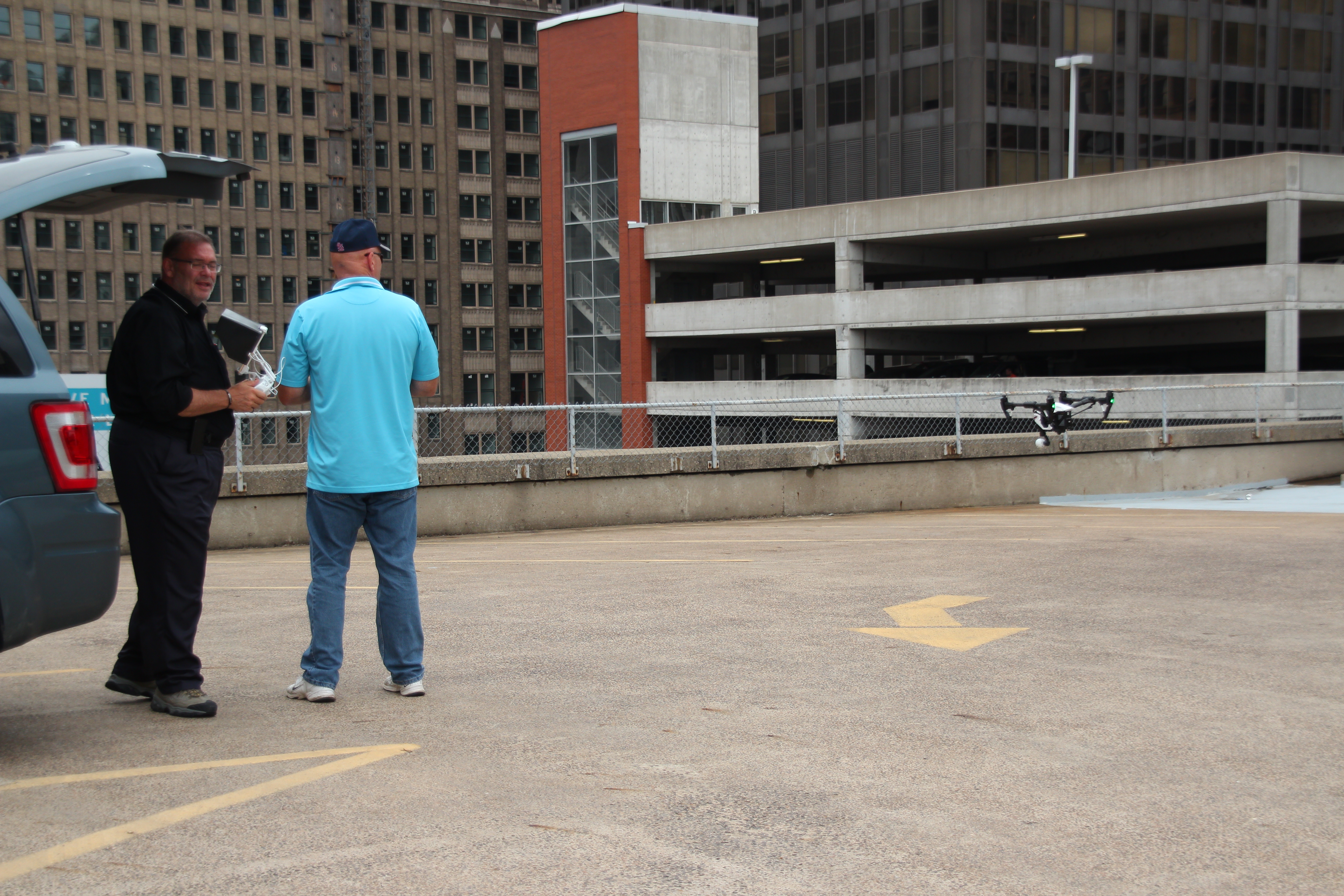

2. Flight Planning and Compliance

Professional operations are always FAA Part 107–compliant and follow local airspace rules. Planning includes:

- Defining safe launch and landing zones

- Establishing altitudes and flight paths for full coverage

- Ensuring we maintain appropriate stand-off distances from people and property

- Coordinating timing so the roof has a strong enough temperature differential (typically late afternoon or early evening after solar loading)

All of this is handled before a drone ever leaves the ground.

3. Data Capture: Thermal and Visual

During the flight, the drone captures:

- High-overlap thermal imagery for later mapping and analysis

- High-resolution RGB photos for visual context, documentation, and reporting

- Close-up visuals of penetrations, seams, rooftop units, and terminations as needed

The goal is not just pretty pictures, but actionable data—imagery that can be correlated to specific locations, units, and features on your roof.

4. Analysis and Interpretation

Once the data is captured, the post-production work begins:

- Stitching imagery into orthomosaic maps

- Calibrating thermal data and reviewing for patterns, anomalies, and false positives

- Cross-referencing thermal hotspots with visual images to distinguish moisture, ponding water, reflectivity issues, or equipment heat

Professional teams understand that not every hot or cold spot is a leak. Experience with commercial roof systems and thermography is critical to correctly interpreting what the camera is seeing.

5. Deliverables You Can Use

A good inspection doesn’t end with a folder of images. It should give you clear, decision-ready deliverables, such as:

- A written summary report in plain language

- Annotated thermal maps highlighting areas of concern

- Side-by-side thermal and visual images of problem zones

- Suggested next steps, whether that’s invasive testing, targeted repairs, or ongoing monitoring

- Optional visual assets (photos and video) that you can use for internal presentations, facility documentation, and stakeholder communications

Turning Roof Data Into Communication and Marketing Assets

For many organizations, building performance and resilience are no longer “back-of-house” topics. They are front-and-center in:

- Investor presentations

- Corporate responsibility reports

- Recruitment and culture materials

- Tenant communications and leasing collateral

Professionally shot aerial video and stills from your thermal inspection can be repurposed to:

- Demonstrate your commitment to proactive maintenance and safety

- Highlight energy-efficiency initiatives and sustainability projects

- Illustrate capital improvements in a way that is easy for non-technical stakeholders to grasp

When your inspection partner is also an experienced commercial video production team, the same mission can produce both technical documentation and polished visual storytelling.

What to Look for in a Drone Thermal Inspection Partner

If you’re evaluating vendors, a few key criteria help separate a basic drone operator from a professional production and inspection partner:

- Experience with commercial roofs, not just general drone flying

- Licensed, insured pilots who understand airspace, risk management, and industrial environments

- Radiometric-capable thermal cameras for accurate temperature data

- A proven post-production workflow for reports, mapping, and visual deliverables

- The ability to integrate inspection footage into broader marketing or documentation efforts

- Capability to operate safely in tight or indoor spaces, when specialized drones are required

When these elements come together, you get more than a one-off inspection—you get a visual and thermal data partner for your facilities portfolio.

Why St Louis Video Production Is a Smart Choice for Drone Roof Thermal Inspections

As an experienced videographer, photographer, and producer at St Louis Video Production, I’ve seen firsthand how combining technical inspection work with high-end visual production gives organizations a powerful advantage. You’re not only identifying problems early—you’re also building a library of visuals that serve facilities, risk management, marketing, and leadership teams simultaneously.

St Louis Video Production is a full-service professional commercial photography and video production company with the right equipment and experienced creative crew for successful image acquisition on complex sites—roofs included. We offer full-service studio and location video and photography, along with editing, post-production, and licensed drone pilots who understand both storytelling and technical capture.

We can customize your productions for diverse media requirements, whether you need a focused thermal inspection report, a facilities update for executives, or a full marketing piece around your building upgrades. Repurposing your existing photography and video branding to gain more traction across channels is another core specialty. Our team is well-versed in all common file types, media formats, and software platforms, making it easy to plug our work into your internal systems and vendors.

We also leverage the latest in Artificial Intelligence across our media services—from intelligent footage organization and enhanced image analysis to smart editing workflows that keep projects efficient and on schedule.

Our private studio lighting and visual setup is ideal for small productions, executive interviews, and explainer segments that can accompany your inspection visuals. The studio is large enough to incorporate props and set elements that help tell your facility story in a compelling way. On every project, we support the full production lifecycle—from setting up a private, custom interview studio to supplying professional sound and camera operators, as well as providing the right equipment on site—so your next video or inspection-driven communication is seamless and successful.

When rooftop access is limited or specialized perspectives are needed, we can even fly our specialized drones indoors where appropriate and safe, capturing unique visuals that traditional crews cannot.

As a full-service video and photography production corporation serving the St. Louis area since 1982, St Louis Video Production has partnered with countless businesses, marketing firms, and creative agencies on their marketing photography and video. If you’re exploring commercial roof thermal inspections by drone—or looking to turn technical inspections into clear, compelling visual stories—our team is ready to help you see your buildings differently, from the roof down.